Lean has been one of the most commonly adopted improvement methodology for the past several decades. However, many vouch that its impact had not been big enough for them or it had not been sustainable. The most common challenge has been a failure to turn Lean into an organizational culture. Why Toyota has been so successful with the Toyota Production System (From which Lean came about), and Lean has not been successful for many organizations?

In my observation of several hundred organizations who have adopted Lean (mostly my clients all over Asia) the successful ones had taken a more systemic and integrated approach to Lean. I call this the Real Lean.

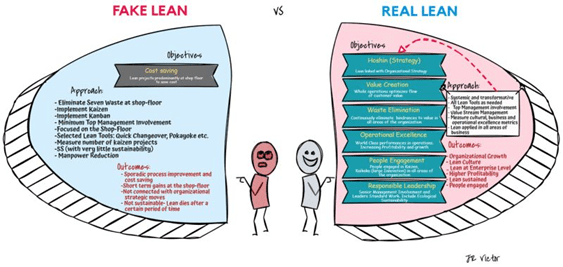

Fake Lean is very Lean-Tool based, focused on Cost Savings, whereas Real Lean had been successful in using lean to drive organizational strategy and growth. Real Lean implementers had also put in much emphasis on People engagement and development rather than a narrow approach by Fake Lean implementers who had wanted to just reduce headcounts to achieve cost savings.

My infographics below; Fake Lean vs Real Lean may be helpful to differentiate the two. Embrace Real Lean and go for an ongoing and lasting success and growth in your organization. In my 20 over years of experience I’ve never seen Lean to fail when it’s DONE RIGHT- THE REAL LEAN

J Ramesh Victor

One Response